A countersunk head tapping screw is a type of fastener that is commonly used in various applications to join materials together. It is specifically designed to create a flush or recessed finish when driven into a pre-drilled hole.

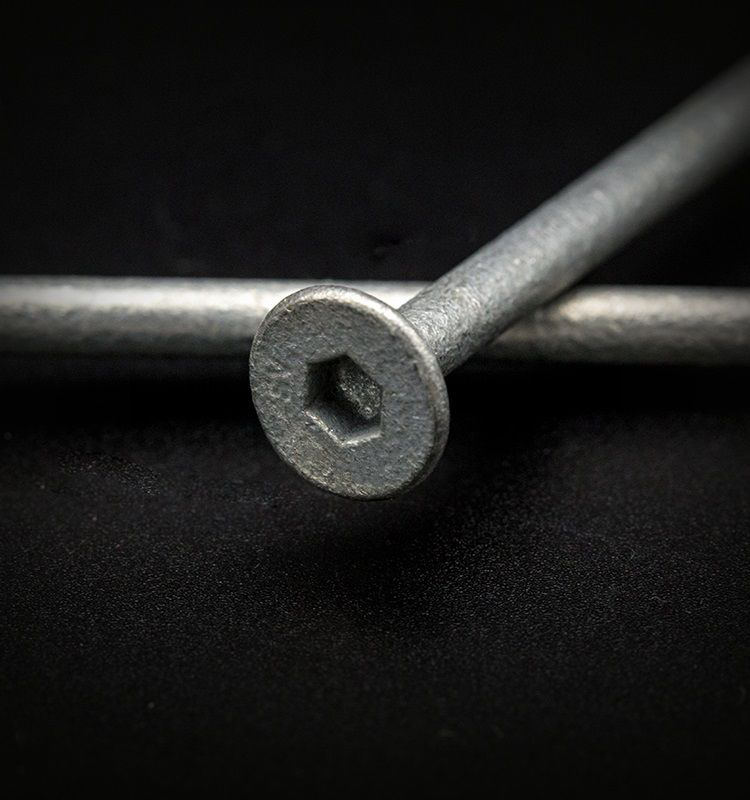

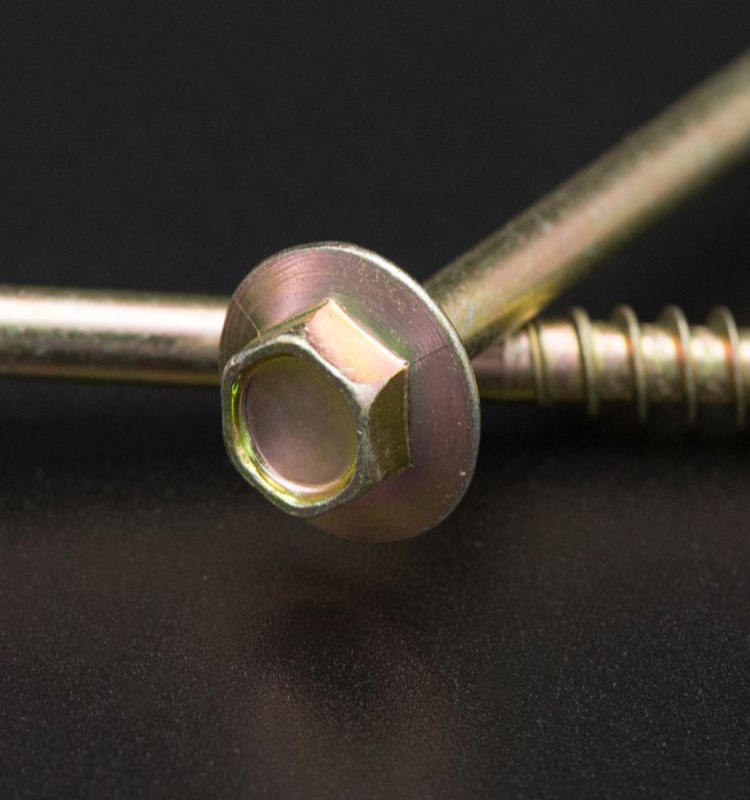

The main distinguishing feature of a countersunk head tapping screw is its head shape. The head is cone-shaped, tapering down to a flat top with a chamfered edge. This design allows the screw to sit flush with the surface or slightly below it when fully driven in, creating a smooth and even appearance.

Countersunk head tapping screws typically have a self-tapping feature, which means they can create their own threads as they are driven into the material, without the need for pre-tapping or pre-threading. This feature eliminates the need for a separate tapping operation and makes the installation process more efficient.

These screws are commonly made from various materials such as steel, stainless steel, or brass, depending on the application requirements. They come in different sizes and thread types to accommodate different materials and thicknesses.

Countersunk head tapping screws are widely used in woodworking, metalworking, and general construction projects. They are commonly employed to fasten materials such as wood, metal, plastic, and composite materials. The flush finish they provide makes them ideal for applications where aesthetics are important or where a protruding fastener could cause interference or snagging.