Screws are among the most fundamental fasteners in construction and manufacturing, but not all screws are created equal. While standard screws serve general purposes, non-standard screws are designed for specialized applications, offering unique features that improve performance in specific scenarios. Two notable examples are drywall screws and Hi-Low thread screws, each engineered for distinct tasks. This article explores their characteristics, uses, and key differences.

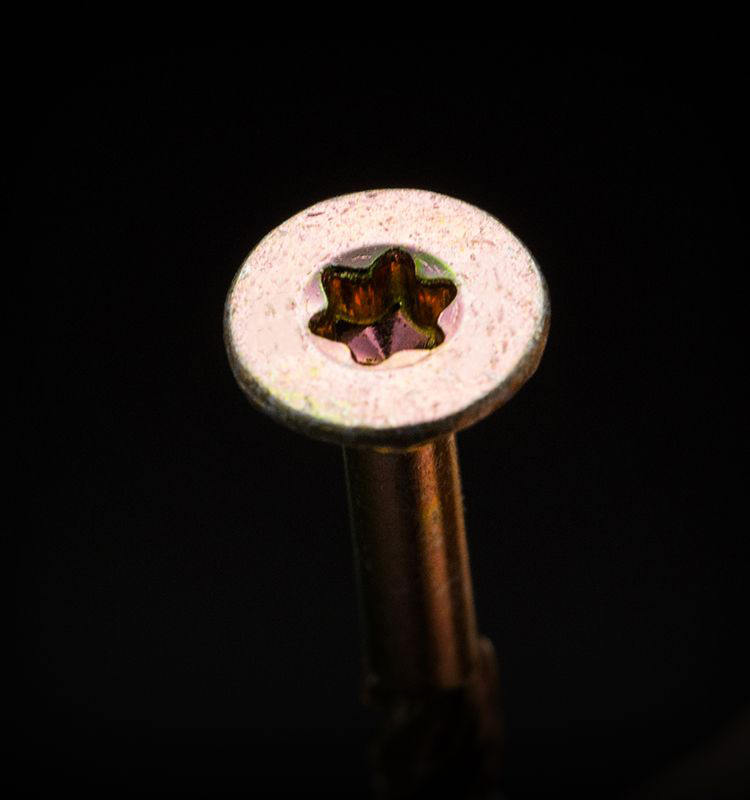

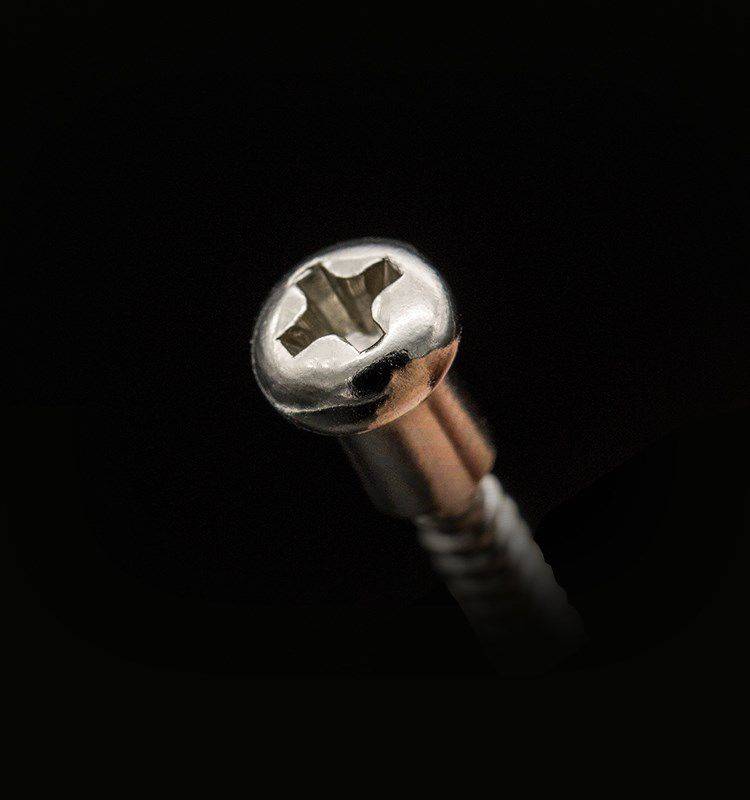

Cross -headed head Hi-Low Thread Screws (hot -dip galvanized)

Drywall Screws: The Essential Fastener for Wallboard Installation

Drywall screws are a type of non-standard screw specifically designed for securing drywall (gypsum board) to wooden or metal studs. Their unique features include:

Fine, sharp threads – Optimized for gripping drywall without tearing the paper surface.

Bugle head design – Helps countersink the screw smoothly without breaking the drywall surface.

Black phosphate or ceramic coating – Provides corrosion resistance and reduces friction during installation.

Key Data Comparison: Drywall Screws vs. Standard Wood Screws

| Feature | Drywall Screws | Standard Wood Screws |

|---|---|---|

| Thread Type | Fine, sharp | Coarse, deep |

| Head Design | Bugle head | Flat or round head |

| Coating | Black phosphate | Zinc or uncoated |

| Primary Use | Drywall attachment | General wood fastening |

Drywall screws are not suitable for load-bearing applications, as they lack the shear strength of structural screws.

Hi-Low Thread Screws: Enhanced Grip for Soft Materials

Hi-Low thread screws (also known as twinfast or dual-thread screws) feature alternating high and low threads, providing several advantages:

Reduced driving torque – The lower threads decrease resistance, making installation easier.

Improved pull-out resistance – The higher threads enhance grip in soft materials like particleboard and MDF.

Prevents material splitting – The design reduces stress on wood fibers.

Key Data Comparison: Hi-Low Thread vs. Standard Thread Screws

| Feature | Hi-Low Thread Screws | Standard Thread Screws |

|---|---|---|

| Thread Pattern | Alternating high/low | Uniform pitch |

| Driving Torque | Lower | Higher |

| Best For | Particleboard, MDF | Solid wood, metal |

Hi-Low thread screws are commonly used in furniture manufacturing and cabinetry, where soft composite materials require secure fastening without splitting.